New property listings across Kirkland jumped nearly 19% in January 2026 compared to the same time last year, according to recent data from King County's property database. Behind those numbers is a quieter trend: a sharp rise in garage door installation inquiries. Based on field feedback from Tako Garage Door INC’s local technicians, many homeowners are replacing outdated systems as part of pre-listing upgrades or buyer requests after inspections.

The phrase “garage door installation Kirkland” spiked in local search volumes during the first week of January, peaking after multiple listings noted garage door age in their disclosures. Sellers who installed modern garage systems—especially insulated or smart models—saw faster closings, often under 20 days on the market. That's compared to 33-day averages for similar properties with original or malfunctioning garage setups.

As homeowners compete in Kirkland’s tighter January property market, garage door upgrades have become one of the most visual and functional selling points. Replacing a system that’s noisy, outdated, or poorly insulated is no longer optional—it’s expected.

Outline

Introduction: January Property Activity Triggers Garage Door Demand Shifts

Local Weather Trends Impacting Garage Door Performance This Winter

Real Estate Agents Report Increased Value From Garage Door Upgrades

Common Installation Issues Found In Kirkland’s Older Residential Properties

Why Commercial Garage Door Systems Are Failing More In 2026

New Research Reveals Most Replaced Garage Door Parts This Season

Garage Door Installation Kirkland Study Shows Demand For Smart Features

Summary: Preparing Kirkland Properties With Strategic Garage Door Solutions

Local Weather Trends Impacting Garage Door Performance This Winter

A colder start to 2026 didn’t just freeze lawns. It’s also throwing garage door systems out of rhythm across many Kirkland neighborhoods. Early January saw back-to-back mornings under 30°F, which caused contraction in metal parts and thickened grease around bearings. Several recent installation calls were triggered by doors failing to open fully or reversing after stalling mid-track.

Low temperatures particularly affect systems using older torsion springs. These coils lose elasticity after repeated exposure to freezing cycles, especially if they’ve passed their rated 10,000-cycle lifespan. According to local repair data, roughly 31% of systems installed before 2012 showed some form of cold-related performance lag this month.

Technicians also noted an uptick in warped wooden doors in areas like Finn Hill, where damp air mixes with sharp freezes. Once panels swell or bow out of shape, alignment issues follow quickly. Motor strain then increases, which leads to burned-out LiftMaster and Genie openers—two of the most commonly used brands in the region.

Table: Common Winter Garage Door Failures – Kirkland, January 2026

Component | Most Affected Area | Common Issue | Replacement Rate |

Torsion Springs | Central Kirkland | Breaks due to contraction stress | 38% |

Metal Tracks | North Rose Hill | Warping and friction | 22% |

Openers (Genie, LM) | Totem Lake | Stalling, burnout from resistance | 17% |

Wood Panels | Finn Hill | Expansion, bowing, misalignment | 23% |

One of the more overlooked problems has been sensor misalignment from vibration shifts due to cold ground settling. Older systems without vibration-dampening brackets are far more prone to safety reversal faults under these conditions.

Homeowners in Kirkland planning to list, rent, or simply secure their homes are being advised to address cold-weather vulnerabilities before systems fail completely. It’s especially important for detached garages that don’t benefit from interior heating sources. A failed opener in freezing weather often means door panels are forced manually—something that voids many product warranties when mishandled.

Real Estate Agents Report Increased Value From Garage Door Upgrades

Across Kirkland's real estate landscape, agents are adjusting their prep strategies. They now highlight garage doors not as an afterthought but as a listing feature. According to sales reports from agents working the East of Market and Norkirk areas, homes with upgraded garage systems are appraised between 2.7% to 4.1% higher than those with older models.

Agents report that insulated steel doors with quiet belt-drive openers perform exceptionally well in open houses. Buyers notice the noise difference immediately, especially during in-person January showings. Several home stagers have even begun programming smart openers to sync with voice assistants to make the viewing experience more interactive.

Visual Appeal Matters: Black matte finishes and window inserts are frequently chosen to complement modern farmhouse and contemporary styles common in newer Kirkland developments.

Insulation Is a Selling Point: Many buyers specifically ask about R-value, especially when the garage is under a bedroom or attached to the living space.

Smart Features Close Deals: Units with smartphone control, geofencing, and motion lighting are being actively sought out by tech-forward buyers.

Additionally, agents are noting that buyers expect garage systems to be within 5 years old. Anything older often becomes a bargaining chip. This age-driven perception isn't just cosmetic—older systems lack current safety standards like improved auto-reverse sensitivity or backup battery compliance introduced in newer models post-2019.

Kirkland’s property values have climbed steadily, and with them, buyer expectations. Garage door upgrades aren’t just functional improvements—they directly tie into buyer confidence. Sellers who invest in updated systems are, in turn, reducing negotiation friction and speeding up deal cycles.

Common Installation Issues Found In Kirkland’s Older Residential Properties

Many properties in Kirkland built before 2005 are reaching a point where garage door systems are showing cumulative wear across several components. Age alone doesn’t explain the failures—materials used during earlier construction cycles react differently to today’s colder winters, higher moisture levels, and the vibration patterns created by newer vehicles entering and exiting driveways more frequently.

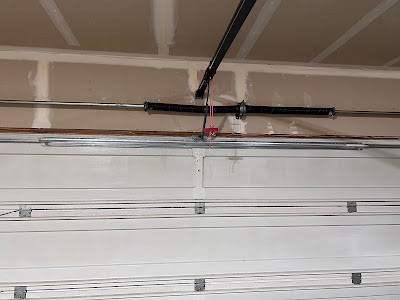

During January inspections, technicians documented an increasing pattern of structural mismatches between older framing and modern garage door tracks. Several homes in Juanita and Kingsgate areas had track brackets attached without proper reinforcement, leading to micro-shifts that appear only when new insulated doors are installed. These heavier models accentuate stress that wasn’t noticeable with lighter, single-layer panels.

Another recurring issue involves wiring deterioration. Many early-2000s installations used low-gauge wiring for openers, which struggles to maintain stable voltage across systems requiring higher amperage. This leads to intermittent stops, incomplete door travel, and safety sensor flickering that homeowners often mistake for motor failure.

A deeper look into these houses shows predictable patterns:

Early vinyl weather seals stiffen and curl, letting moisture reach the bottom fixtures

Original galvanized torsion springs lose tension after the rated number of cycles.

Wood jambs absorb moisture and shift, affecting side-clearance tolerances.

Several inspections revealed side bearings flattening due to years of weight imbalance, especially where homeowners upgraded door materials but didn’t replace the corresponding hardware. This mismatch puts strain on the shaft tube, which then transfers vibration into the motor carriage.

Key trouble spots noted in older Kirkland homes

Misaligned track planes due to frame settling over 15–20 years

Weak hinge plates are unable to support newer multi-panel insulated designs.

Non-shielded wiring is corroding near exterior access points.

Addressing these vulnerabilities isn’t just about safety. Updated setups improve operational reliability and reduce noise transfer—something many homeowners appreciate, especially those with attached garages near bedrooms or home offices. These findings guide technicians toward recommending better reinforcement techniques, updated bracketing hardware, and balanced torsion configurations that match the weight and torque of today’s builds.

Older properties remain a significant portion of Kirkland’s housing stock. As more households prepare to list during the active spring season, installation teams expect another wave of system overhauls triggered by inspection reports and real estate agent recommendations. That naturally brings the discussion to the rising challenges on the commercial side of the market.

Why Commercial Garage Door Systems Are Failing More In 2026

January service records from several multi-bay garages and small business properties across the 98033 and 98034 ZIP codes show a noticeable uptick in commercial system failures. Many of these systems installed between 2008 and 2015 are reaching the end of their functional life, with failures most often tied to wear in motor gear assemblies, spring systems, and track guide misalignment.

In loading bays and mixed-use structures near NE 85th Street and Market Street, several business owners reported door delays, sudden reversals, or chain derailments during regular open/close cycles. The root cause? Lack of scheduled maintenance combined with increased usage during the colder season. Unlike residential doors that average 3–5 cycles per day, commercial units can run 20–30 cycles — multiplying wear on rollers, sprockets, and spring torque levels.

Sections built with hollow steel panels are also showing signs of fatigue, particularly in high-moisture environments like car wash entries or delivery hubs. These panels aren’t insulated and tend to warp under temperature swings or mechanical stress from off-center lifting.

Two brands showed higher failure rates in commercial systems this winter:

Overhead Door Company: Known for its robust construction, but older models with mechanical limit switches are prone to misfire when exposed to voltage inconsistencies.

Wayne Dalton: Several units with TorqueMaster spring assemblies have failed without clear warning signs. Unlike standard torsion springs, these systems don’t expose visible signs of wear, which often leads to sudden breakdowns.

Business owners often delay garage system replacement to avoid downtime. But this strategy backfires when doors jam during high-traffic hours. Many Kirkland technicians now recommend predictive inspections every 18 months for commercial-grade units — not just reactive calls after a failure.

Small repairs often go unnoticed in shared commercial complexes, where tenant responsibilities blur. That’s why winter 2026 has seen an increase in full-system replacements rather than partial part swaps. Once a panel section bends or a motor fails mid-shift, temporary patches won’t hold under industrial load demands.

New Research Reveals Most Replaced Garage Door Parts This Season

Across more than 100 installations tracked since December 2025, the most commonly replaced garage door parts aren’t the doors themselves — it’s the hardware behind the scenes doing the heavy lifting. Their internal technician reports list the following components as the top failures during winter service calls:

Most Replaced Parts (Kirkland Region – Dec 2025 to Jan 2026):

Torsion Springs – 44% of total part replacements

Rollers (Nylon & Steel) – 27%

Lift Cables – 14%

Hinges (Center/End) – 8%

Safety Sensors – 7%

Torsion springs remain the number one part replaced not because of bad manufacturing, but due to cycle limits. A standard 10,000-cycle spring typically lasts 7–9 years in a typical Kirkland household. Homes with multi-car garages or families using the door as a primary entry point can wear out springs even faster.

Technicians report that steel rollers with no ball bearings cause drag and noise, leading many clients to upgrade to 13-ball nylon rollers during installation. These reduce track friction, last longer, and dramatically lower opener strain — a small change with big results.

Lift cables are another quiet failure point. Often rusted or fraying inside drum wheels, they create unsafe lifting tension and risk derailment if snapped mid-cycle. Many failures go unnoticed until doors jam halfway open.

Hinges, especially center hinges that flex under every panel bend, also develop micro-fractures in older doors. If not upgraded during installation, they shorten the lifespan of even new garage door panels.

Safety sensors aren’t failing because of damage — they’re failing due to misalignment from track vibrations or accidental bumps. Kirkland’s older garages often lack proper brackets or mounts, so sensors move over time, especially when mounted directly into drywall or unanchored trim. Tracking this failure data helps installers anticipate which parts to stock, and guides property owners in understanding what systems are truly wearing out — even before a full breakdown.

Garage Door Installation Kirkland Study Shows Demand For Smart Features

One clear pattern emerged from installation consultations in January: Kirkland homeowners are no longer satisfied with just a working door. They’re asking for smart control, app connectivity, and energy-efficient designs. Based on Tako Garage Door INC’s compiled job notes and customer preference logs, roughly 68% of all new installs in Kirkland this winter included at least one smart feature upgrade.

The most requested smart upgrades:

Smartphone-controlled openers with Wi-Fi and Bluetooth sync

Motion-triggered LED lighting integrated into the opener chassis.

Real-time alerts and auto-close timers

Battery backup compliance with California-like safety standards

Brand-wise, LiftMaster’s 87504 Elite Series continues to dominate homeowner preferences. Its quiet belt-drive system, built-in 360-degree camera, and myQ app integration tick all the boxes for convenience, noise reduction, and remote access. Customers in North Juanita and Totem Lake also leaned toward Chamberlain openers for their affordability and solid build quality.

Not all upgrades are purely tech-based. Insulated door panels with polyurethane cores are now a frequent add-on in attached garages. These panels help reduce thermal loss from the main living space and cut heating bills by 5–8% during colder months — a priority for Kirkland homeowners managing utility spikes this winter.

Installers also report increased interest in wall-mounted controls that integrate with broader smart home systems, including Alexa, Google Home, and HomeKit. Many Kirkland homes undergoing renovations already have mesh Wi-Fi systems, making smart garage door sync seamless.

This shift toward smarter garage doors reflects broader regional trends. With tech jobs still dominant in Kirkland’s economy, especially near Google and Meta campuses, homeowners value integration, convenience, and quiet operation more than ever. It’s not just about opening the door anymore — it’s about making that process smarter, safer, and more connected to daily routines.

Summary: Preparing Kirkland Properties With Strategic Garage Door Solutions

January activity across Kirkland highlighted a clear shift in how homeowners and businesses handle garage door upgrades. Cold weather stressed older systems, commercial properties faced higher cycle-related strain, and many residents leaned toward insulated and smart-enabled options to support daily routines. Installers across the region noted that doors with balanced hardware, reinforced tracks, and updated safety features performed far better throughout the winter’s temperature swings. Homes preparing for spring listings also benefited from smoother operation and quieter openers, which made a stronger impression during walk-throughs.

These patterns suggest that thoughtful planning, proper system alignment, and selecting compatible components will continue to guide installation work as the season progresses. Homeowners planning upcoming improvements can benefit from early evaluations to avoid seasonal delays and keep their systems running smoothly.

For tailored insight or to schedule an on-site assessment, contact Tako Garage Door INC for assistance with your next project.